With all the mechanical parts assembled all that is left is firmware calibration – or so we thought.

With all basic calibration done we noticed on prints that the X and Y axises were shifting. as shown below. Looking around and asking on communities this seems often to be due to when the stepper motors skips steps or the timing belt slipping.

We tried everything suggested, from cooling stepper drivers, motors, tightening belts and turning down acceleration in the firmware but nothing worked.

It was first when we loosened the belts and ran the motors we noticed that the pulleys were slipping off the shafts. This was because the pulleys screws were biting into the brass pipe which we used to bridge the gap between our motors and the pulleys did not provide enough friction. When we loosened the belts even less friction was applied between the brass and drive shaft and the slippage became apparent.

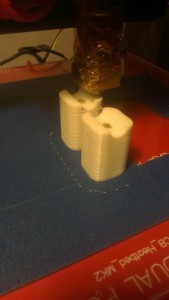

After buying some metal epoxy to fixate everything together we are able to finally produce perfectly straight prints!

The print above are some holders for a spool where I designed the feet myself.

It’s quite an amazing feeling to draw something in a 3D program one day and to hold it the next.